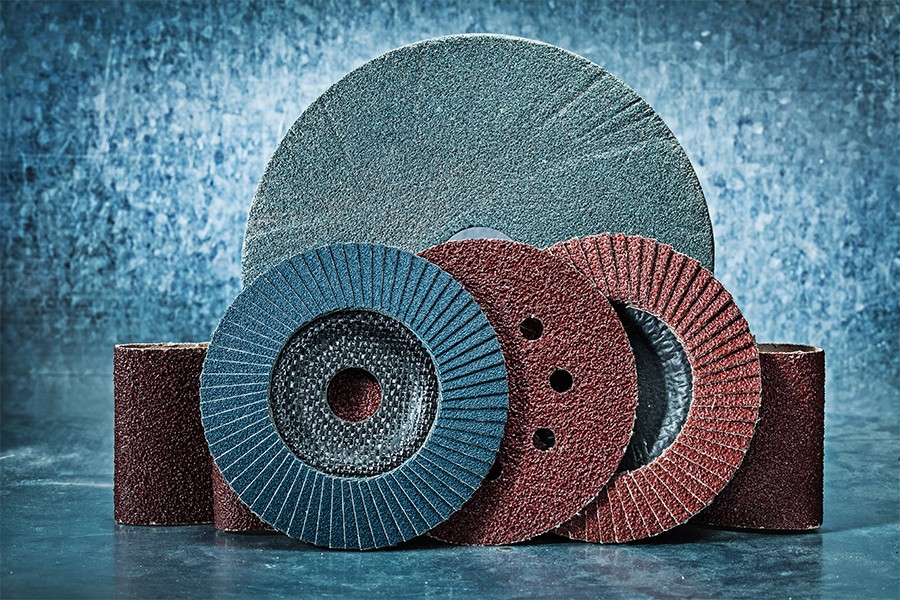

Flap Discs

In the hands of an expert crafter or DIY enthusiast, the right tools can make a big difference. When it comes to surface preparation or finishing tasks, one of the tools that consistently stands out is the flap disc.

What is Flap Disc?

Flap discs are versatile grinding tools that combine the grinding action of a conventional disc with the finishing function of a sanding disc. They consist of many small pieces of abrasive material (known as "fins") attached to a disc in an overlapping pattern. Blades are typically made from aluminum oxide or zirconia, but ceramic is becoming increasingly popular due to its ability to grind at higher speeds. The configuration of these fins on the disc makes them the perfect choice for a variety of tasks, from aggressive grinding to fine mixing and finishing.

How Flap Discs Work

The operation of flap discs is quite simple. As the disc rotates, overlapping abrasive blades "hit" the surface of the work material, gradually abrading the surface layers. As the blades wear, fresh abrasive material is constantly released, providing a consistent cutting action throughout the life of the disc. This means flap discs do not need to be replaced as often as other types of abrasive discs, saving time and increasing productivity.

The Versatility of Flap Discs

One of the most important advantages of flap discs is their versatility. They can be used on a variety of materials and for a wide variety of applications, including metal, wood and plastic:

- Grinding: Flap discs can be used for high stock removal tasks, making them ideal for deburring, edge grinding and weld seam removal.

- Finishing: Cover discs can provide a smooth finish with their overlapping flap structures and are perfect for tasks such as surface mixing and conditioning.

- Sanding: Flap discs can also be used for sanding tasks, smoothing surfaces in preparation for painting or sealing.

Choosing the Right Flap Disc

Selecting the appropriate flap disc depends on the task at hand and the material you are working with. Coarse-grained (lower numbers) discs are suitable for aggressive grinding work, while finer-grained (higher numbers) discs are ideal for finishing work. Also consider the type of abrasive material. Aluminum oxide flap discs are versatile and suitable for most materials, while zirconia or ceramic discs are preferred for harder materials or high speed grinding. Flap discs represent a fusion of design and functionality, providing a powerful and versatile tool in the field of abrasive technology. Whether you're a professional looking to optimize your workflow or a DIY enthusiast looking to improve the quality of your work, understanding and using the power of flap discs can dramatically improve your abrasive experience.