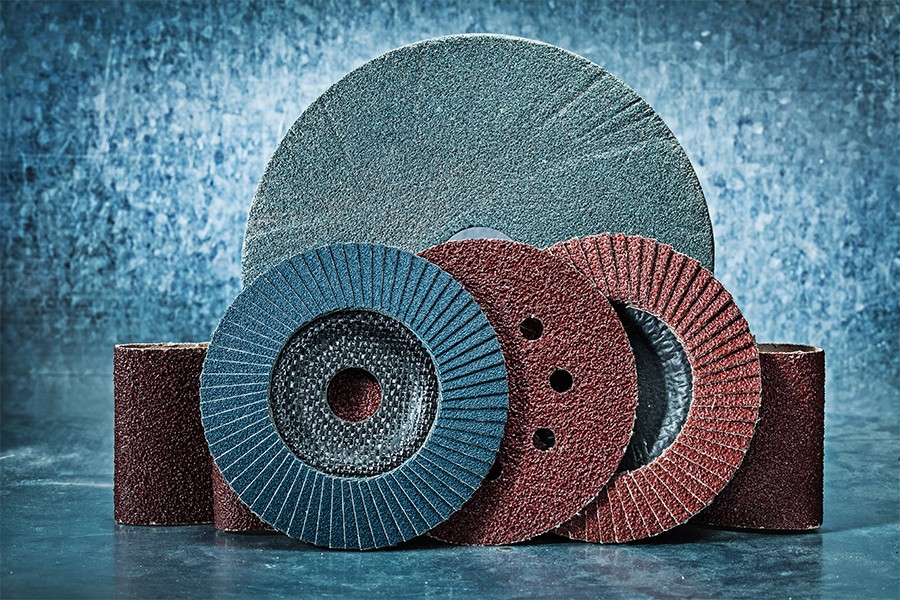

Coated Abrasives

When it comes to smoothing rough edges, achieving a perfect finish, or prepping surfaces for paint, one tool always comes to mind: coated abrasives. While this category of hardware may seem simple or straightforward, there is a world of complexity and usefulness beneath the surface.

What are Coated Abrasives?

The most common example of a coated abrasive is undoubtedly sandpaper, a household name known even to those who aren't keen on do-it-yourself projects. However, coated abrasives are more than just sandpaper. It includes a range of products such as abrasive tapes, discs and sheets. In essence, coated abrasives consist of an adhesive layer on one side that binds the abrasive grains to a backing material. The backing may be paper, fabric, or a combination of both, depending on the intended application.

How Do Coated Abrasives Work

Coated abrasives work by using the abrasive grains to "scratch" the surface of the workpiece. The hardness, size and distribution of abrasive grains on the backing material significantly affect the level of material removal and the quality of the finish. The removal process can be likened to using a series of small, extremely hard chisels to continuously chip off a surface, resulting in a smoother surface.

Applications of Coated Abrasives

- Surface Preparation: Whether you are preparing a wall for a new coat of paint or preparing to paint a piece of furniture, coated abrasives are your best friend. They can effectively remove old paint, correct imperfections, and create the ideal surface for paint or stain to adhere to.

- Woodworking: Coated abrasives for woodworkers play a crucial role in shaping and finishing projects. Sandpaper and its cousins are invaluable tools in the woodworking shop, from leveling a freshly glued panel to adding the finishing touch to a wood masterpiece.

- Metalworking: Coated abrasives also find use in the metalworking industry. They are used for tasks such as removing burrs, rust and oxidation or providing a brushed or satin finish on metal surfaces.

- Automotive: In the automotive world, coated abrasives are used for everything from repairing and smoothing bodywork to repairing and polishing headlights.

Choosing the Right Coated Abrasive

Choosing the right coated abrasive largely depends on the task at hand. Important considerations include the type of material you are working with, the level of finish you want, and the amount of material you need to remove. Also important is the type of abrasive grain: aluminum oxide grains are durable and versatile, making them suitable for a variety of materials, while silicon carbide grains are ideal for working on harder materials and producing a finer surface. It is much more than meets the eye. They are a testament to the synergy of simple ingredients that make up an extremely useful tool. Whether you're a carpenter hobbyist, a professional metalworker or a DIY enthusiast, understanding and using coated abrasives can dramatically improve the quality of your work and the satisfaction you get from it. After all, the perfect finish is just a sandpaper away!