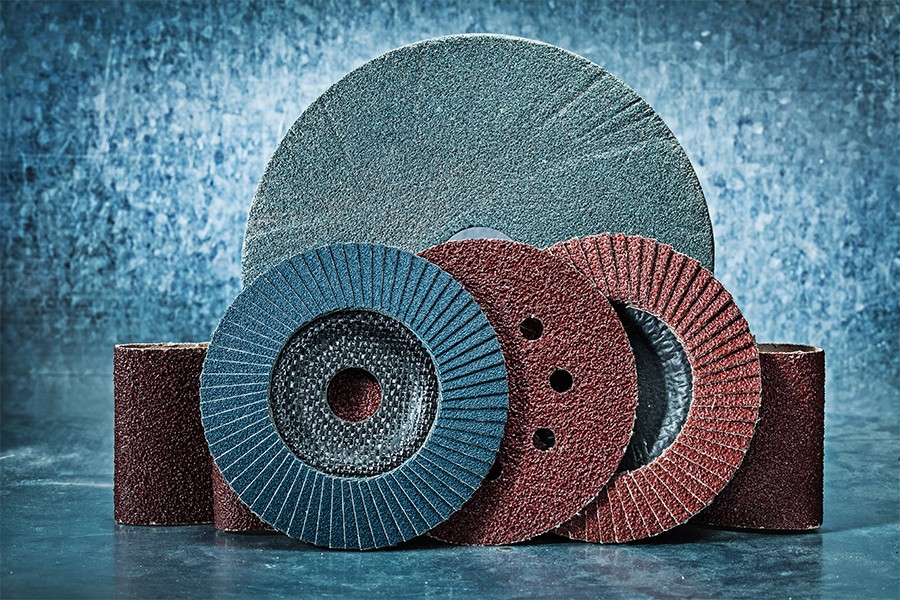

Abrasives

Playing an important role in shaping, smoothing and finishing surfaces in the hardware world, from wood and metal to ceramic and plastic, Abrasives are indispensable tools in industries ranging from shaping the hardest materials to giving them a polished look and precision jewellery.

What Are Abrasives?

Abrasives are substances used for grinding, polishing or cleaning hard surfaces. They work by friction and their success largely depends on their hardness and grain size. Abrasives can be in natural forms such as diamond or emery, or in synthetic forms such as silicon carbide or aluminum oxide.

Abrasive Types

- Coated Abrasives: This category includes sandpaper, the most common abrasive. Coated abrasives have an adhesive layer on one side that adheres the abrasive grains to a backing material. They're perfect for removing material from surfaces, whether you're preparing a wall for painting or leveling a woodworking project.

- Bonded Abrasives: These include grinding wheels and cutting discs. They consist of abrasive grains held together in a matrix of glass, resin or rubber. Bonded abrasives are typically used in heavy-duty applications such as metal cutting or grinding.

- Super abrasives: These are extremely hard abrasives, typically diamond or cubic boron nitride (CBN). Designed for heavy-duty precision work such as grinding very hard materials or achieving very fine finishes.

- Non-Woven Abrasives: These consist of abrasive grains suspended in a non-woven (usually nylon) matrix. They are ideal for tasks such as deburring, cleaning and providing a satin finish.

- Sand and Powders: Typically used for lapping or polishing, these abrasives typically consist of finely ground abrasive particles. They provide a very fine, mirror-like surface.

How to Choose the Right Abrasive?

- Hardness: The abrasive should be harder than the material you are working with. For example, a diamond abrasive will be required to work on hardened steel or gemstones.

- Grain Size: This refers to the size of individual abrasive grains. Coarser grits (lower numbers) remove more material but leave a rougher surface. Finer grits (higher numbers) remove less material but leave a smoother surface.

- Durability: Certain tasks may require abrasives that can withstand high pressure or temperature.

- Compatibility: Make sure the abrasive is compatible with the backing material and all the achines you will be using it with.

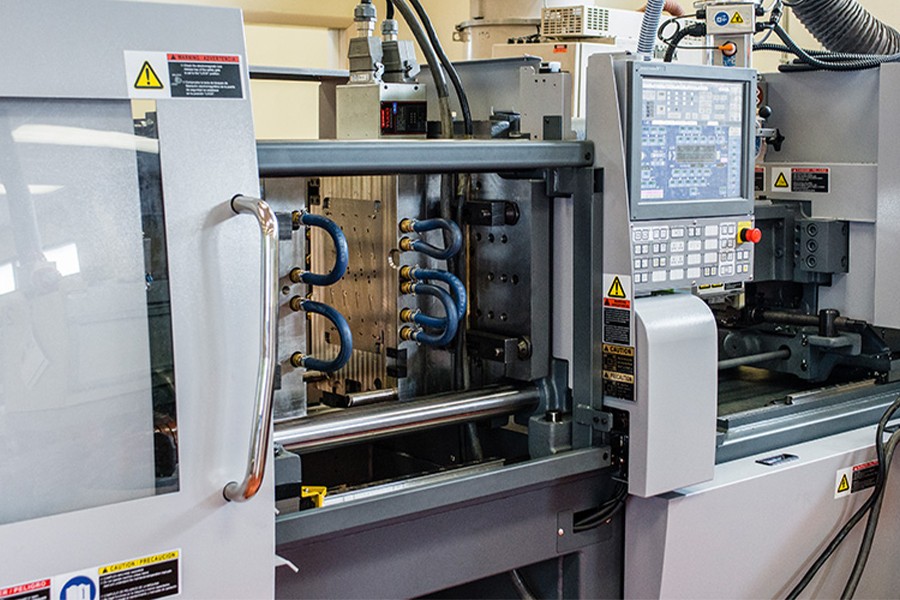

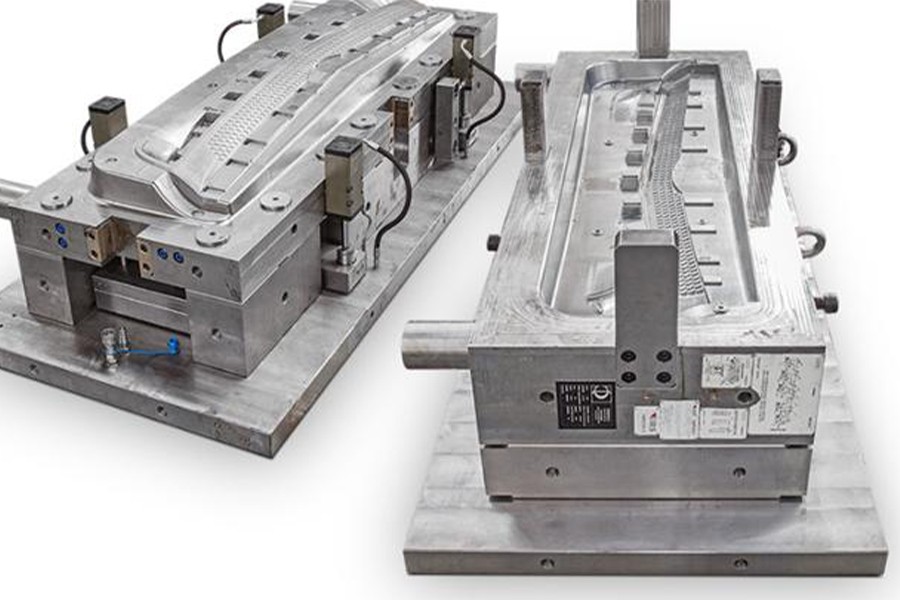

Horeganefe manufactures R&D, Design, Mold and Plastic Injection parts for the Hardware, Automotive and White Goods sectors. Its 15 years of experience in the sectors has enabled it to partner with global brands since its establishment. We offer you the abrasives in Horeganefe's product range in the highest quality as auxiliary elements in production.